Value Delivered

For the Texas Children’s Hospital, we removed and replaced air handling units with minimal disruption to their day-to-day operations. To accommodate a unique location around an existing building column, we custom-built one of two new air handling units.

This project had to be completed while maintaining airflow and pressurization within the 24/7/365 hospital environment, so we installed temporary air handling capacity. This helped maintain a comfortable environment while the hospital waited for their permanent units.

Because we worked in shifts, 24 hours a day, the job was delivered safely and quickly, helping our client achieve optimal conditions in key facility spaces.

Client Objectives

The hospital wanted to maximize airflow to radiology, magnetic resonance imaging, multiple research laboratories, and other vital areas.

Solutions

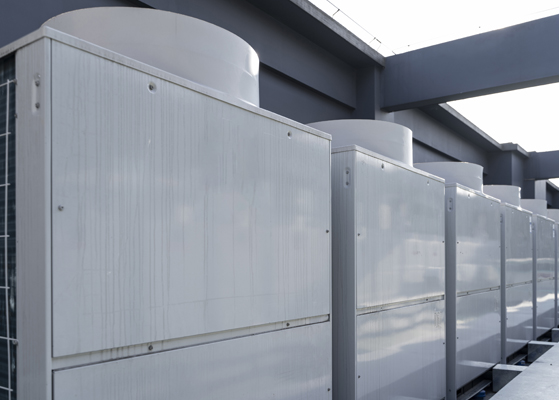

To remove two 40-year-old air handling units—including the largest in the hospital—and install replacement units, our solutions included:

- A custom-built unit consisting of individual panels, fans, a 125-horsepower motor, chilled water coils, and steam coils

- A modular production air handling unit with a 30-horsepower motor

- Two temporary direct expansion cooling units

- A temporary chilled water unit

- Two temporary electric heating units

- Two temporary return air fans

- 30 temporary spot cooling units in critical areas

Client Background

Texas Children’s Hospital is a nationally-ranked acute care pediatric hospital.